Life Without Sun: Earth's Alien Hydrothermal Vent Worlds

TL;DR: Geckos climb walls using billions of microscopic hairs that harness van der Waals forces. Scientists have replicated this natural adhesive to create revolutionary technologies for robotics, medicine, and consumer products.

Picture a gecko casually strolling across your ceiling, defying gravity with each step. That seemingly effortless feat has puzzled scientists for generations, and the answer lies in structures so small you'd need a powerful microscope to see them. Within the next decade, the same forces that let geckos walk on walls will help surgeons seal wounds without stitches, enable robots to scale skyscrapers for inspection, and give you phone cases that stick to any surface without leaving residue.

The secret? Billions of microscopic hairs working in concert to harness one of nature's most fundamental forces. What researchers discovered about gecko feet has transformed materials science and launched a revolution in adhesive technology.

A gecko's foot is an engineering marvel. Each toe pad contains roughly 500,000 tiny hairs called setae, and every single seta branches into hundreds of even tinier structures called spatulae. Think of it like a tree: the seta is the trunk, and the spatulae are the leaves, except these "leaves" measure just 200 nanometers across - about 500 times smaller than a human hair.

The numbers are staggering. A single seta measures roughly 110 micrometers long and 4.2 micrometers wide, with each one branching into up to 1,000 spatulae. These triangular spatulae are the real heroes of the story, creating an enormous surface area that gets incredibly close to whatever surface the gecko touches.

But here's where it gets interesting. These aren't suction cups or sticky secretions. Geckos produce no glue. Instead, they exploit a fundamental force of nature that exists between all atoms and molecules.

Van der Waals forces sound exotic, but they're actually one of the most common forces in nature. These weak attractions occur between molecules when they get close enough together - we're talking distances measured in fractions of a nanometer. Individually, each interaction is incredibly weak. But multiply that tiny force by billions of contact points, and you get something powerful enough to support a gecko's entire body weight on a vertical surface.

The beauty of this system lies in its reversibility. When a gecko wants to stick, it curls its toes to maximize contact between spatulae and the surface, engaging van der Waals forces across millions of contact points. To release, it simply changes the angle of its toes, peeling them away like removing tape. This happens in milliseconds, allowing geckos to scurry at impressive speeds.

A single seta can generate up to 200 micronewtons of force - enough to lift the weight of an ant. Multiply that by half a million setae per toe, and you've got serious adhesive power. A gecko could theoretically support 133 kilograms with just one toe. The animal only uses a fraction of its adhesive capacity during normal climbing.

Recent research revealed another layer to this story. Scientists at NIST discovered that gecko feet are coated with an ultra-thin layer of lipids that helps keep them sticky even after repeated use. This nanoscale coating prevents contamination and maintains the intimate contact needed for van der Waals forces to work their magic.

The quest to understand gecko adhesion reads like a scientific detective story. For decades, researchers proposed everything from suction to electrostatic attraction. Some thought geckos secreted sticky fluids. Others believed micro-interlocking with surface irregularities explained the phenomenon.

The breakthrough came in 2000, when biologists finally confirmed that van der Waals forces were the primary mechanism. Using atomic force microscopy and careful measurements, they demonstrated that the billions of spatulae create enough cumulative attractive force to support the gecko's weight. The revelation sparked immediate interest in engineering circles.

By 2002, researchers began creating synthetic versions of gecko setae, marking the birth of a new field. Early prototypes used polymer fibers arranged to mimic natural setae. They worked, but not as well as the real thing. The challenge was replicating nature's precision at nanoscale.

The field exploded after that initial success. Labs worldwide raced to create better synthetic adhesives, each iteration bringing improvements in strength, durability, and ease of manufacture.

Creating artificial gecko adhesives turned out to be remarkably difficult. Nature had 100 million years to perfect the design through evolution. Engineers had to compress that timeline into a few years of intensive research.

The first major advance came with carbon nanotube arrays. Researchers grew forests of tiny carbon tubes that mimicked the structure of setae and spatulae. The results were impressive: these materials achieved shear stresses of 36 Newtons per square centimeter, nearly four times stronger than actual gecko feet. But carbon nanotubes proved expensive and difficult to manufacture at scale.

Scientists explored alternatives. Polymer-based synthetic setae offered easier manufacturing and lower costs. Various research teams experimented with different materials: polyimide, polyurethane, polydimethylsiloxane. Each material brought trade-offs between adhesive strength, durability, flexibility, and cost.

One persistent challenge was the self-cleaning property of gecko feet. Real gecko setae naturally shed dirt and debris - a crucial feature for adhesives used in dusty environments. Researchers discovered that the hierarchical structure itself contributes to self-cleaning, as particles larger than the spatulae spacing simply don't make good contact.

Modern synthetic gecko adhesives come in various forms. Some use microscale pillars topped with thin flaps that maximize surface contact. Others employ wedge-shaped structures that provide directional adhesion - they stick when pushed one way but release when pulled another. This mimics how geckos control attachment through toe angle.

The robotics applications emerged quickly. In 2010, researchers demonstrated Stickybot, a climbing robot that used gecko-inspired adhesives to scale vertical surfaces. The robot could climb glass, tile, and even some rough surfaces, though it required carefully controlled motions to maintain adhesion.

Since then, gecko-inspired climbing robots have grown increasingly sophisticated. Researchers have built robots that can transition from floor to wall to ceiling, maintaining adhesion through complex three-dimensional environments. These machines don't need bulky suction pumps or magnetic systems - just the right materials and motion control.

The military and inspection industries showed immediate interest. A robot that could climb buildings or navigate complex industrial infrastructure without ropes or scaffolding had obvious utility. Companies began developing prototypes for inspecting bridges, power plants, and skyscrapers.

One particularly innovative application involved climbing robots for spacecraft. In the microgravity of space, traditional adhesion methods don't work well, but van der Waals forces function the same way regardless of gravity. NASA funded research into gecko-inspired grippers that could help robots navigate on asteroids or repair satellites.

The technology keeps improving. Modern gecko-climbing robots can carry payloads several times their own weight while maintaining stable adhesion. Researchers have developed "smart" adhesives that respond to electrical signals, allowing robots to precisely control when and where they stick.

Perhaps the most exciting applications lie in medicine. Traditional surgical adhesives often irritate tissue or lose strength when wet. Gecko-inspired adhesives offered a potential solution - strong, biocompatible, and reversible attachment even in moist environments.

Researchers developed bandages using gecko-inspired microstructures that could seal wounds without sutures. The materials stick firmly to skin and tissue but can be removed without causing damage or leaving residue. For patients, this means less scarring and faster recovery.

The technology has expanded into surgical applications. Surgeons need adhesives that work on wet, moving organs - think of trying to patch a balloon while it's inflating and deflating. Gecko-inspired materials can maintain adhesion on beating hearts or expanding lungs, potentially replacing sutures in delicate procedures.

Drug delivery represents another frontier. Researchers are developing patches with gecko-inspired adhesion that stick reliably to internal organs or tissues, delivering medication exactly where needed. Unlike traditional patches that might shift or fall off, these maintain position through the body's natural movements.

The materials are being tested for tissue engineering applications as well. Growing new organs or repairing damaged tissue often requires scaffolds that cells can attach to and grow on. Gecko-inspired surfaces provide controllable adhesion without chemical modifications that might interfere with cell behavior.

Consumer applications are starting to reach the market. Phone accessories, hooks, and mounting systems using gecko-inspired adhesion principles promise to stick strongly but remove cleanly without residue. Unlike conventional tape or adhesive pads, these products can be washed and reused thousands of times.

The appeal is obvious. How many times have you struggled to mount something on a wall without drilling holes or leaving sticky residue? Gecko-inspired products offer a middle ground between permanent mounting and flimsy suction cups.

Manufacturing improvements have made these products increasingly affordable. Early synthetic setae required expensive cleanroom fabrication. Modern production methods use roll-to-roll manufacturing processes similar to printing, dramatically reducing costs.

But commercial success has been slower than researchers initially hoped. Real-world conditions - dust, oils, varied surface textures - pose challenges that laboratory tests don't always reveal. Companies are learning that the gap between "works in the lab" and "works in your garage" can be substantial.

Still, the technology is maturing. Several companies now offer gecko-inspired gripping pads for industrial automation, where robots need to manipulate objects without damaging them. The automotive industry uses them for assembly processes. Electronics manufacturers employ them for handling delicate components.

Moving from laboratory demonstrations to mass production has proven complex. Nature builds gecko setae through biological growth processes we can't easily replicate in factories. The hierarchical structure - large structures subdividing into smaller ones - requires sophisticated manufacturing techniques.

Cost remains a significant barrier for many applications. While prices have dropped considerably, gecko-inspired adhesives still cost more than traditional tapes and glues for most purposes. The technology excels in niche applications where its unique properties justify the premium, but competing with commodity adhesives on price alone remains difficult.

Durability presents another challenge. Natural gecko setae last the animal's lifetime, shedding dirt and maintaining performance through thousands of attachment cycles. Synthetic versions degrade faster, especially in harsh conditions. Researchers continue working on materials that better match nature's resilience.

Surface compatibility varies widely. Gecko adhesives work brilliantly on smooth surfaces like glass but struggle on rough or porous materials. Engineers are developing hierarchical structures that work across a broader range of textures, but there's a fundamental trade-off: structures optimized for smooth surfaces don't perform as well on rough ones, and vice versa.

The environmental implications of gecko-inspired adhesives look promising. Traditional adhesives often use solvents and chemicals that pose disposal challenges. Many can't be recycled or reused. Gecko adhesives, by contrast, rely on physical structures rather than chemical bonding, making them inherently more sustainable.

Reusability is a key advantage. A gecko-inspired pad might replace thousands of disposable tape strips over its lifetime. In industrial settings, this translates to reduced waste and lower long-term costs. For consumers, it means fewer trips to the store for replacement adhesive products.

The materials themselves present fewer environmental concerns than traditional adhesives. Most synthetic gecko adhesives use relatively benign polymers rather than reactive chemicals. When their useful life ends, they can often be recycled like other plastics.

However, the manufacturing process currently requires significant energy, particularly for high-precision nanoscale structures. As production methods improve and scale up, the energy intensity should decrease. Researchers are exploring bio-based polymers that could reduce the carbon footprint further.

Where does this technology go next? Researchers are pursuing several exciting directions. Switchable adhesives that respond to light, heat, or electrical signals could revolutionize manufacturing and robotics. Imagine a robotic gripper that can grab objects firmly and release them instantly on command, without complex mechanical systems.

Combining gecko adhesion with other properties opens new possibilities. Scientists have created materials that are both adhesive and conductive, useful for flexible electronics. Others are developing adhesives that change color to indicate when they're properly attached, providing visual feedback for quality control.

The intersection with soft robotics looks particularly promising. Traditional robots use rigid grippers and mechanical fasteners. Soft robots need compliant materials that can handle delicate objects. Gecko-inspired adhesives offer a way to grip without crushing, manipulate without scratching, and release without dropping.

Biomimetic design continues to inspire innovations beyond simple adhesion. Researchers study how geckos integrate adhesion with locomotion, sensory feedback, and motor control. These insights are leading to more sophisticated robotic systems that move more like living creatures.

The journey from observing a gecko on a wall to engineering practical adhesive products spans centuries of scientific investigation and decades of intensive development. We've learned that the most effective solutions often already exist in nature - we just need to understand them well enough to replicate their principles.

Gecko-inspired adhesion represents more than just a clever technological trick. It demonstrates how fundamental physics, biological evolution, and human ingenuity can combine to solve practical problems. The weak van der Waals forces that barely register between individual molecules become powerful tools when deployed at nature's scale.

As manufacturing techniques advance and costs decline, gecko-inspired adhesives will move from specialized applications into everyday products. The robot climbing your office building for window washing might use them. The bandage on your next surgery could employ them. The hook holding your keys might harness the same forces that let geckos defy gravity.

What started as a simple question - how do geckos walk on ceilings? - has blossomed into a technology with implications for medicine, robotics, manufacturing, and consumer products. It's a reminder that nature's solutions, refined over millions of years, often surpass what we can initially imagine. The gecko's foot, optimized through countless generations, continues to teach us new tricks.

The next time you see a gecko effortlessly navigate a vertical surface, remember: you're watching billions of molecular-scale interactions working in perfect coordination. And somewhere, a researcher is studying that movement, dreaming up the next innovation that will bring gecko-power to solve human challenges. The revolution is just getting sticky.

Ahuna Mons on dwarf planet Ceres is the solar system's only confirmed cryovolcano in the asteroid belt - a mountain made of ice and salt that erupted relatively recently. The discovery reveals that small worlds can retain subsurface oceans and geological activity far longer than expected, expanding the range of potentially habitable environments in our solar system.

Scientists discovered 24-hour protein rhythms in cells without DNA, revealing an ancient timekeeping mechanism that predates gene-based clocks by billions of years and exists across all life.

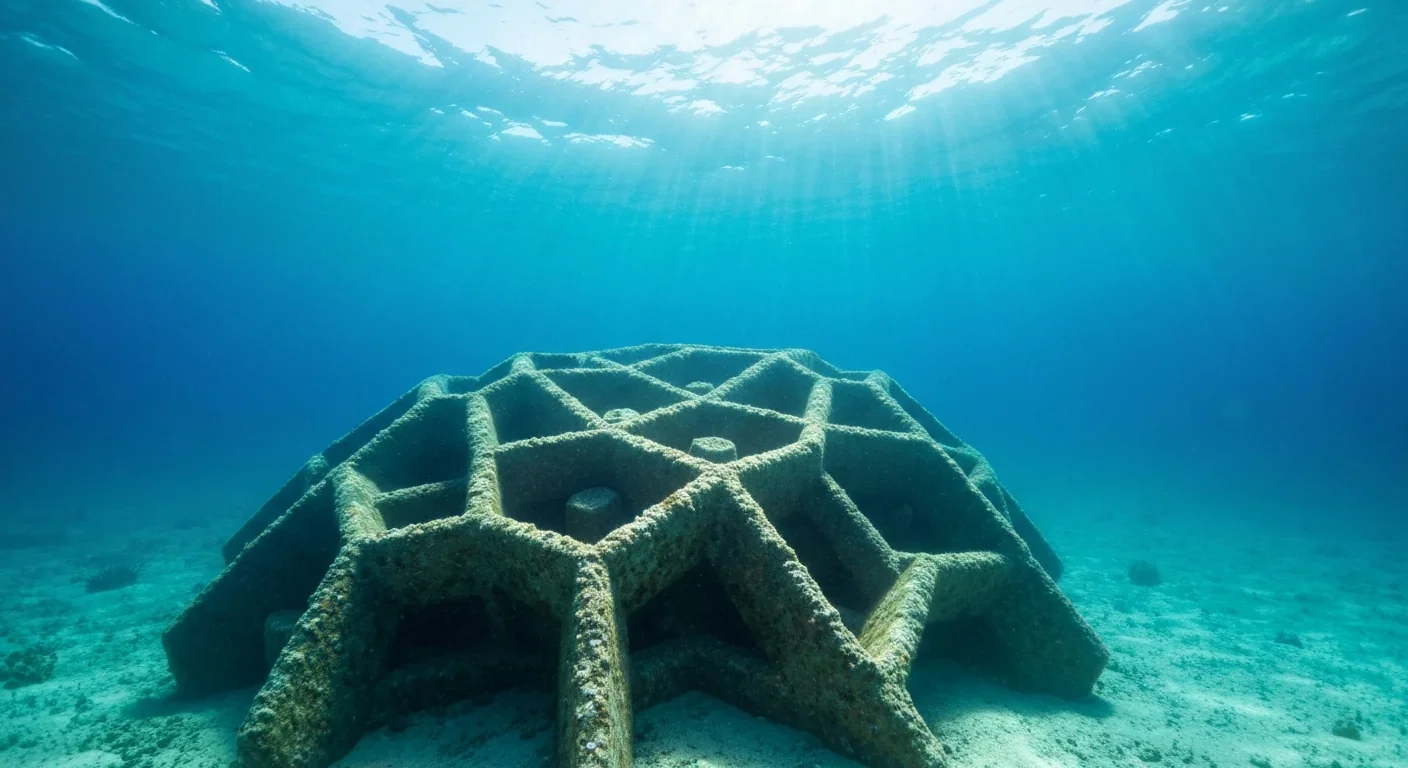

3D-printed coral reefs are being engineered with precise surface textures, material chemistry, and geometric complexity to optimize coral larvae settlement. While early projects show promise - with some designs achieving 80x higher settlement rates - scalability, cost, and the overriding challenge of climate change remain critical obstacles.

The minimal group paradigm shows humans discriminate based on meaningless group labels - like coin flips or shirt colors - revealing that tribalism is hardwired into our brains. Understanding this automatic bias is the first step toward managing it.

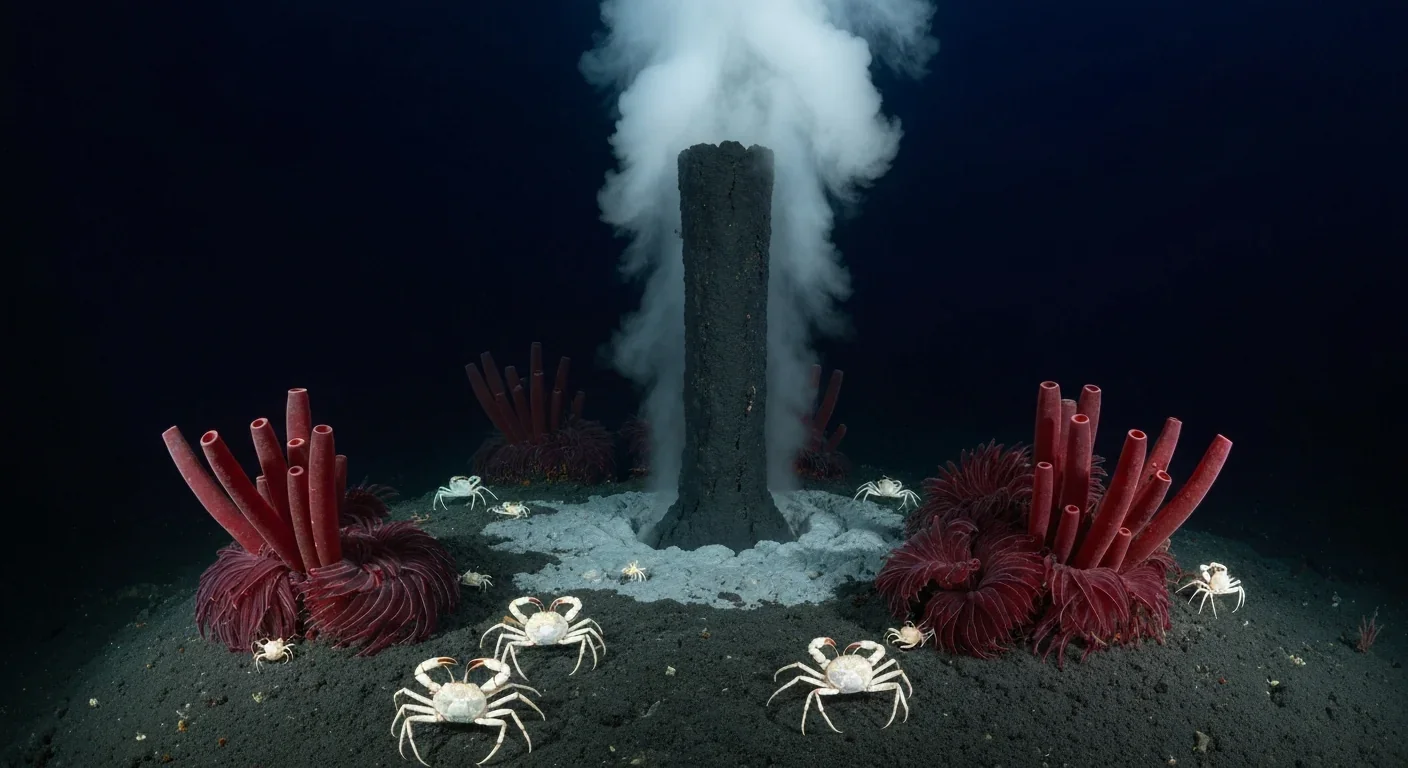

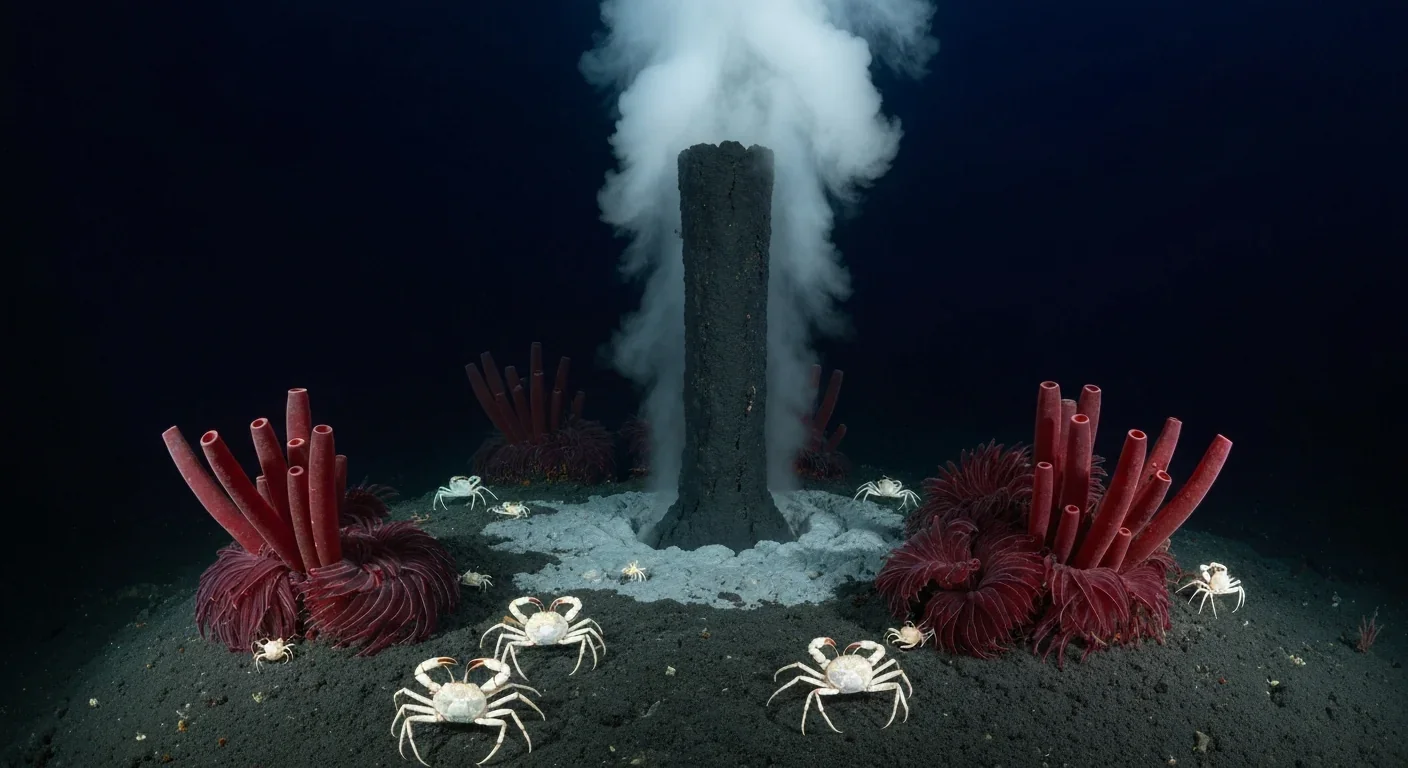

In 1977, scientists discovered thriving ecosystems around underwater volcanic vents powered by chemistry, not sunlight. These alien worlds host bizarre creatures and heat-loving microbes, revolutionizing our understanding of where life can exist on Earth and beyond.

Automated systems in housing - mortgage lending, tenant screening, appraisals, and insurance - systematically discriminate against communities of color by using proxy variables like ZIP codes and credit scores that encode historical racism. While the Fair Housing Act outlawed explicit redlining decades ago, machine learning models trained on biased data reproduce the same patterns at scale. Solutions exist - algorithmic auditing, fairness-aware design, regulatory reform - but require prioritizing equ...

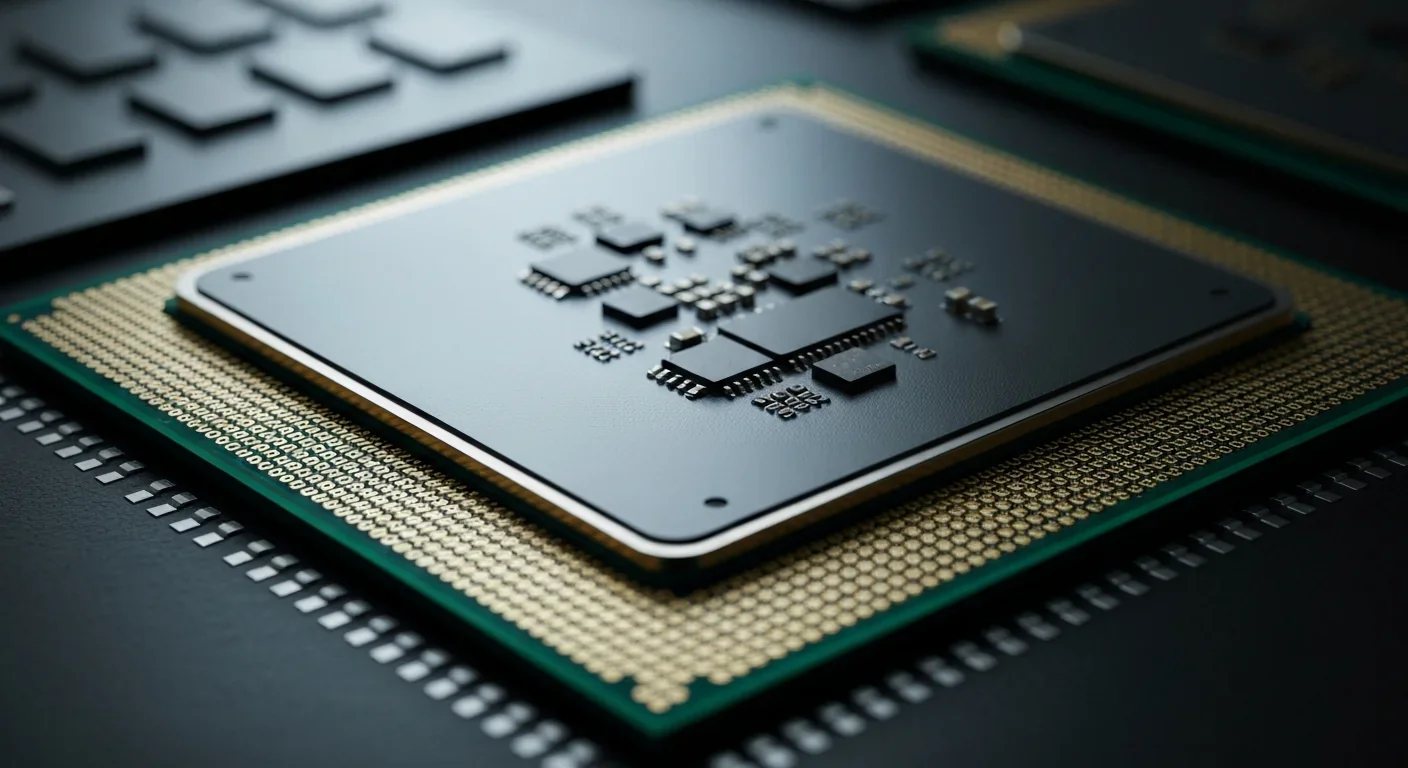

Cache coherence protocols like MESI and MOESI coordinate billions of operations per second to ensure data consistency across multi-core processors. Understanding these invisible hardware mechanisms helps developers write faster parallel code and avoid performance pitfalls.