Life Without Sun: Earth's Alien Hydrothermal Vent Worlds

TL;DR: Scientists have decoded spider silk's secret: liquid crystal protein structures that create strength rivaling steel. This breakthrough enables bio-based materials for aerospace, medicine, and sustainable construction.

Within the next five years, the buildings you work in, the medical devices that save lives, and even the spacecraft exploring Mars could all share something unexpected: a design inspired by the microscopic architecture of spider silk. Scientists have cracked one of nature's most elegant engineering puzzles, discovering that certain spider silk proteins arrange themselves into liquid crystal structures that grant them mechanical properties rivaling or exceeding conventional steel. This isn't just another biomimicry story - it's a fundamental shift in how we understand and create advanced materials.

For decades, researchers knew spider silk was strong. What they didn't understand was why it was so strong. The answer lies in a phenomenon called liquid-liquid crystalline phase separation, where proteins shift between liquid and ordered crystalline states during fiber formation. Major ampullate spidroins - the proteins that make up dragline silk - undergo this phase separation through molecular motifs called "stickers" and "spacers" in their repeat regions.

During spinning, these protein droplets transition from liquid to crystalline states under the influence of shear forces, ion shifts, and pH changes. The result? A β-crystalline structure that gives mature dragline silk its legendary toughness. The tensile strength can reach 1.75 GPa for certain species like Trichonephila clavipes, compared to structural steel's typical 400-550 MPa - making spider silk roughly three to four times stronger, pound for pound.

But strength alone doesn't tell the full story. Spider silk also exhibits remarkable elasticity, able to stretch 30-40% before breaking. This combination of strength and flexibility is what materials scientists call "toughness," and it's what makes spider silk so valuable. Kevlar is strong but brittle; spider silk bends without snapping.

Humans have admired spider silk since antiquity. Ancient Greeks used spider webs to dress wounds, recognizing their antimicrobial properties centuries before germ theory. In Papua New Guinea, indigenous peoples wove fishing nets from the silk of giant orb-weaver spiders - nets strong enough to catch fish weighing several pounds.

The scientific fascination began in earnest during the Industrial Revolution, when microscopes revealed the fiber's extraordinary fineness: a single strand of dragline silk measures just 3-8 micrometers in diameter, roughly one-tenth the width of a human hair. By the 1990s, the U.S. military was funding research into synthetic spider silk for body armor, but early attempts failed because scientists couldn't replicate the silk's natural spinning process.

The problem wasn't the protein sequence - researchers could clone spider silk genes and produce the proteins in bacteria or yeast. The challenge was assembly. Spiders spin silk at room temperature using water-based solutions, while industrial fiber production typically requires high heat, toxic solvents, or extreme pressures. Without understanding the liquid crystal mechanism, attempts to force-spin synthetic silk produced fibers that were strong but lacked the natural material's toughness and elasticity.

Previous technological leaps offer instructive parallels. When humans discovered how to smelt iron around 1200 BCE, it wasn't just about creating a new material - it was about understanding the relationship between temperature, carbon content, and crystalline structure. Similarly, the shift from natural rubber to synthetic polymers in the early 20th century required deep insights into molecular chemistry. Each breakthrough came not from simply copying nature, but from understanding why natural materials worked the way they did.

Think of liquid crystals as a halfway house between chaos and order. In a normal liquid, molecules tumble randomly. In a solid crystal, they're locked in rigid patterns. Liquid crystals occupy the middle ground - molecules can flow like a liquid but maintain some directional order, aligning along preferred axes.

Your smartphone screen probably uses liquid crystals to control light. Spider silk proteins use the same principle to control mechanical properties. Before spinning, spidroins exist in a disordered liquid state within the spider's silk gland. As the protein solution travels through the spinning duct, changes in pH, salt concentration, and mechanical shear trigger the phase separation.

The "stickers" - short amino acid sequences with strong intermolecular attractions - begin to cluster together, forming dense droplets. The "spacers" - more flexible protein segments - connect these clusters, creating a network. Under the right conditions, this network adopts a liquid crystalline arrangement where protein chains align parallel to each other.

When the spider pulls the fiber from its spinnerets, the aligned proteins rapidly crystallize into β-sheet structures: tightly packed, hydrogen-bonded protein chains that form the silk's rigid crystalline regions. These crystals are embedded in a semi-amorphous matrix of less-ordered proteins, creating a composite material at the nanoscale. The crystals provide strength; the amorphous regions provide flexibility.

This isn't just theory. Researchers using small-angle X-ray scattering and polarized light microscopy have directly observed the liquid crystalline droplets forming in synthetic spidroin solutions. They've measured how shear forces align these droplets and tracked the transition to β-crystalline structures. The mechanism is real, observable, and - crucially - replicable.

Armed with this understanding, scientists are now producing artificial spider silk that matches natural silk's properties. The key is mimicking not just the protein sequence, but the spinning process.

Researchers at MIT and other institutions have developed microfluidic devices that replicate the spider's spinning duct, creating gradients of pH and ion concentration that trigger controlled phase separation. By carefully tuning shear rates and draw speeds, they can produce fibers with tensile strengths approaching 1.5 GPa - competitive with natural dragline silk.

Other teams are using generative AI models to design modified spidroin sequences with tailored mechanical properties. Want a fiber that's extra stiff for structural applications? Adjust the ratio of crystalline to amorphous regions. Need something more elastic for medical sutures? Modify the spacer sequences to increase flexibility. The liquid crystal mechanism provides the conceptual framework; computational tools provide the design precision.

Production scalability remains a challenge, but progress is accelerating. Companies like Bolt Threads and Spiber have demonstrated kilometer-scale production of recombinant spider silk, using fermentation tanks filled with engineered microorganisms. These organisms produce spidroin proteins that are then spun into fibers using biomimetic wet-spinning techniques.

The economics are improving too. Early synthetic spider silk cost thousands of dollars per kilogram; current estimates suggest production costs could fall below $100 per kilogram at industrial scale - competitive with high-performance synthetic fibers like aramids.

The aerospace industry is watching closely. Aircraft manufacturers constantly seek materials that reduce weight without sacrificing strength, since every kilogram saved translates to fuel efficiency and increased payload capacity. Spider silk composites could replace carbon fiber in non-critical structures, offering comparable strength with better impact resistance and lower environmental footprint.

NASA has expressed interest in spider silk-based materials for Mars habitats. On Mars, structures must withstand extreme temperature swings, abrasive dust storms, and intense UV radiation while minimizing launch weight. Spider silk's combination of strength, flexibility, and radiation resistance makes it a compelling candidate.

The medical device sector sees even more immediate applications. Surgeons need sutures that are strong, biocompatible, and resorbable - meaning the body can safely break them down over time. Synthetic spider silk sutures could outperform current synthetic options, reducing inflammation and scarring while maintaining tensile strength during the critical healing period.

Artificial tendons and ligaments represent another frontier. Human tendons can withstand stresses up to 100 MPa; spider silk easily exceeds this, suggesting it could serve as a scaffold for tissue engineering. Researchers are exploring hybrid materials that combine spider silk fibers with stem cells, creating living constructs that integrate with the patient's own tissue.

Even the fashion industry is experimenting. Companies have produced prototype garments from spider silk, marketing them as sustainable luxury items. Unlike synthetic fabrics derived from petroleum, spider silk is biodegradable and produced through low-energy biological processes. The challenge is scaling production to meet apparel industry demands, but niche applications - high-end outdoor gear, for instance - could provide early markets.

Perhaps the most profound impact will be on sustainable construction. Concrete and steel dominate modern building, but both carry heavy environmental costs. Cement production alone accounts for roughly 8% of global CO2 emissions. Steel manufacturing consumes vast amounts of energy and generates significant pollution.

Spider silk-based materials offer a potential alternative for certain applications. Imagine structural cables made from synthetic spider silk, supporting suspension bridges with a fraction of the weight of steel cables. Or reinforcing bars for concrete that won't corrode like steel rebar, extending building lifespans and reducing maintenance costs.

These aren't pipe dreams. Researchers have already demonstrated that spider silk fiber composites can achieve compressive and tensile properties suitable for structural applications. The challenge is producing sufficient quantities at competitive prices, but the trajectory is clear.

Beyond mechanical applications, spider silk's unique properties enable entirely new technologies. Its biocompatibility and controllable degradation make it useful for drug delivery systems - microscopic capsules that release medication at predetermined rates. Its optical properties allow it to guide light, suggesting applications in biodegradable photonics.

Researchers are even exploring spider silk scaffolds for tissue engineering. Because the material can be processed into various forms - fibers, films, sponges, hydrogels - it provides versatile platforms for growing replacement tissues and organs. Early studies show neural cells growing along spider silk fibers, raising possibilities for nerve repair.

The path from laboratory to marketplace isn't obstacle-free. Regulatory approval for medical devices is rigorous, requiring years of safety and efficacy testing. Using spider silk in implantable devices will demand exhaustive biocompatibility studies, immunological assessments, and long-term degradation monitoring.

Manufacturing consistency presents another hurdle. Natural spider silk varies in properties depending on the spider's diet, age, and even stress levels. Synthetic production must achieve batch-to-batch uniformity to meet industrial standards. This requires tight control over fermentation conditions, protein purification, and spinning parameters - achievable but not trivial.

Intellectual property disputes could slow adoption. Multiple institutions and companies hold patents on spider silk production methods, protein sequences, and spinning techniques. Navigating this patent landscape will require either licensing agreements or enough innovation to work around existing claims.

There's also the question of whether synthetic spider silk can truly compete with established materials in price-sensitive markets. Steel is cheap, abundant, and backed by a century of engineering knowledge. Displacing it will require not just equivalent performance, but compelling advantages - lighter weight, longer lifespan, or lower total cost of ownership.

Environmental impact deserves scrutiny too. While spider silk itself is biodegradable, producing it via microbial fermentation requires energy, water, and nutrients. A full lifecycle analysis should compare the total environmental footprint of spider silk production against conventional materials, accounting for feedstock sourcing, waste streams, and end-of-life disposal.

Different regions are approaching spider silk development through distinct lenses. Japan, with its traditional reverence for silk and strong biotechnology sector, has invested heavily in recombinant spider silk for medical applications. Japanese researchers have successfully spun continuous fibers with properties matching natural silk and are now focusing on commercialization.

European initiatives emphasize sustainability, viewing spider silk as part of a broader transition to bio-based materials. The European Union's Horizon research program has funded multiple spider silk projects, often in collaboration with textile and chemical companies seeking alternatives to petroleum-derived synthetics.

The United States maintains its focus on defense and aerospace applications, with DARPA and other agencies supporting research into high-performance spider silk composites. American companies are also targeting the lucrative medical device market, where premium pricing can justify initial production costs.

China's approach combines industrial scalability with materials science innovation. Chinese researchers have published extensively on spider silk production and are rapidly building manufacturing capacity. The country's ability to scale biotechnology production could position it as a dominant player in synthetic spider silk markets.

This international competition could accelerate innovation, but it also raises questions about equitable access. If spider silk-based medical devices prove superior but remain expensive, they could exacerbate healthcare disparities. Ensuring widespread access will require deliberate policy choices around intellectual property, technology transfer, and production subsidies.

For individuals and institutions, the spider silk breakthrough offers both opportunities and imperatives. Materials scientists and bioengineers should familiarize themselves with liquid crystal physics and protein engineering - domains that were once specialized niches but are becoming central to advanced materials development.

Industries currently dependent on petroleum-based synthetics should monitor spider silk progress as a potential disruption. Fashion brands, in particular, may find consumer demand shifting toward bio-based materials, making early adoption a competitive advantage.

Policymakers face choices about how to encourage innovation while managing risks. Regulatory frameworks for bio-based materials need updating to reflect their unique properties - neither purely biological nor purely synthetic. Investment in research infrastructure, particularly shared facilities for pilot-scale production, could help bridge the gap between laboratory success and commercial viability.

Educators should integrate biomimicry and bio-based materials into engineering curricula, preparing the next generation to think beyond conventional material categories. The future belongs to those who can navigate the interfaces between biology, chemistry, physics, and engineering.

The spider, hanging in its web, doesn't know it's a master materials engineer. It simply spins, guided by millions of years of evolutionary refinement. But now that we understand the liquid crystal mechanism behind silk's remarkable properties, we can do something no spider can: we can improve on it.

Generative models are already designing spidroin variants that outperform natural silk in specific properties. Hybrid materials combine spider silk with carbon nanotubes or graphene, creating composites with extraordinary characteristics. The boundary between natural and synthetic is blurring, giving way to a new category: programmable biological materials.

This is where spider silk's true significance emerges. It's not just about replacing steel or creating better sutures. It's about demonstrating that we can decode nature's manufacturing principles and apply them at industrial scale. If we can do this with spider silk, what else becomes possible?

Imagine growing buildings instead of constructing them, using engineered organisms to deposit structural materials layer by layer. Envision clothing that repairs itself, embedded with biological mechanisms that mend tears and reinforce stress points. Consider medical implants that adapt to the patient's body, changing properties as healing progresses.

These scenarios sound like science fiction, but they're logical extensions of the principles revealed by spider silk research. Once we truly understand how to control phase transitions in biological polymers, we gain access to a vast design space that conventional manufacturing can't reach.

The spider's web, glistening in the morning dew, has been a symbol of delicate beauty for millennia. Now it's becoming something else: a blueprint for humanity's material future. And unlike steel mills or concrete plants, this blueprint is written in the language of life itself - renewable, adaptable, and elegant in its efficiency.

The revolution won't happen overnight. Regulatory pathways need clearing, manufacturing must scale, and markets must develop. But the fundamental science is sound, the applications are compelling, and the trajectory is clear. We're not just learning from spiders anymore. We're joining them as architects of high-performance biological materials.

Within a decade, you'll likely encounter spider silk-derived materials in your daily life without even realizing it - in the surgical mesh that speeds your recovery, the ultra-light backpack you carry, or the sustainable building materials in your office. The question isn't whether the spider silk revolution will happen. It's whether we'll be ready when it does.

Ahuna Mons on dwarf planet Ceres is the solar system's only confirmed cryovolcano in the asteroid belt - a mountain made of ice and salt that erupted relatively recently. The discovery reveals that small worlds can retain subsurface oceans and geological activity far longer than expected, expanding the range of potentially habitable environments in our solar system.

Scientists discovered 24-hour protein rhythms in cells without DNA, revealing an ancient timekeeping mechanism that predates gene-based clocks by billions of years and exists across all life.

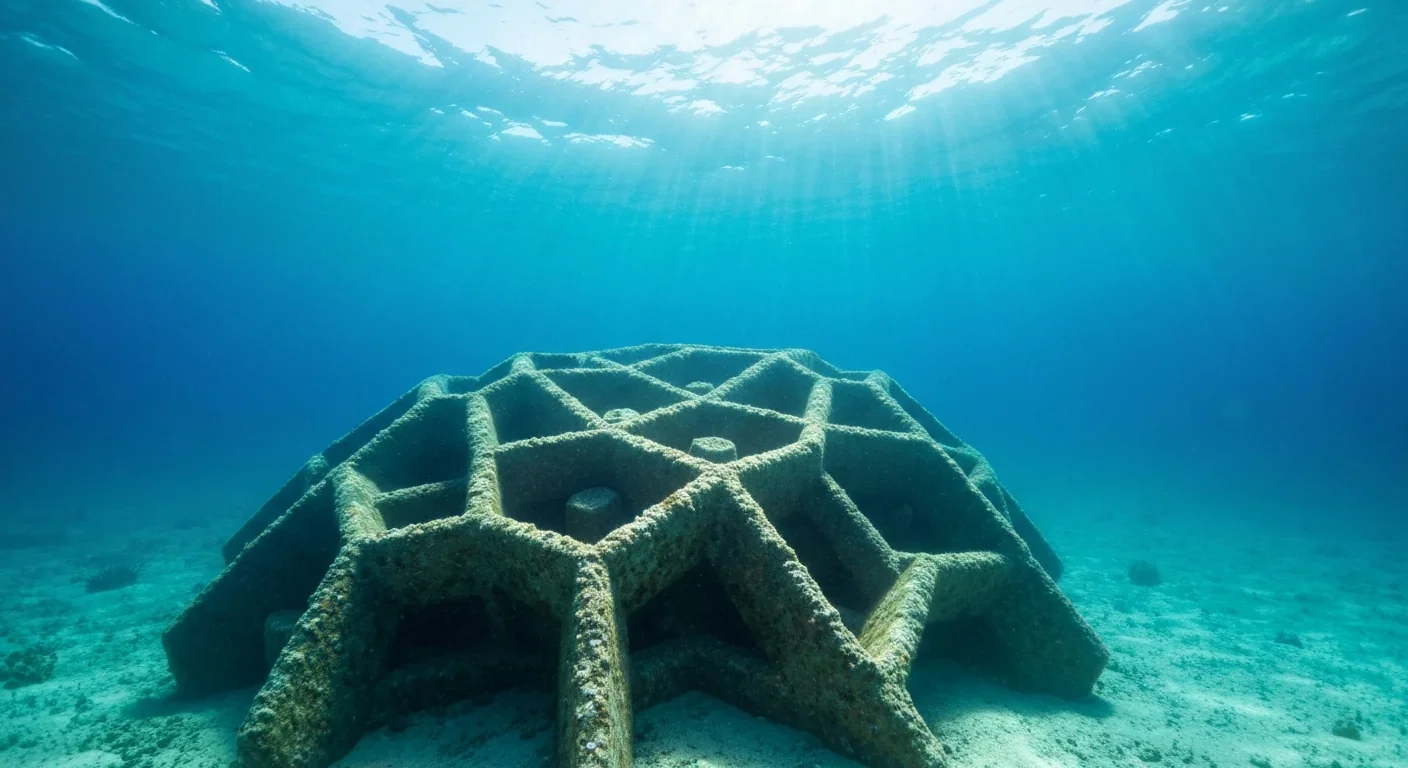

3D-printed coral reefs are being engineered with precise surface textures, material chemistry, and geometric complexity to optimize coral larvae settlement. While early projects show promise - with some designs achieving 80x higher settlement rates - scalability, cost, and the overriding challenge of climate change remain critical obstacles.

The minimal group paradigm shows humans discriminate based on meaningless group labels - like coin flips or shirt colors - revealing that tribalism is hardwired into our brains. Understanding this automatic bias is the first step toward managing it.

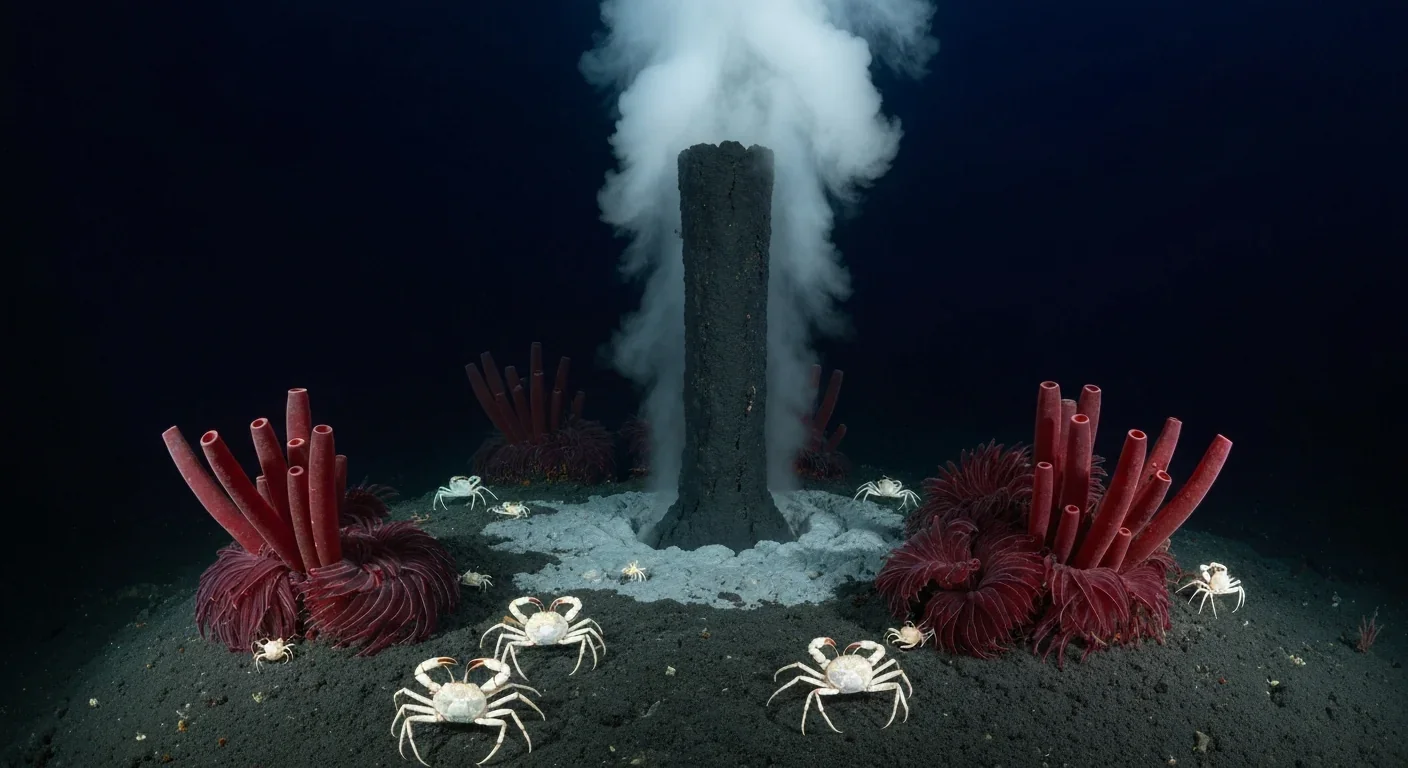

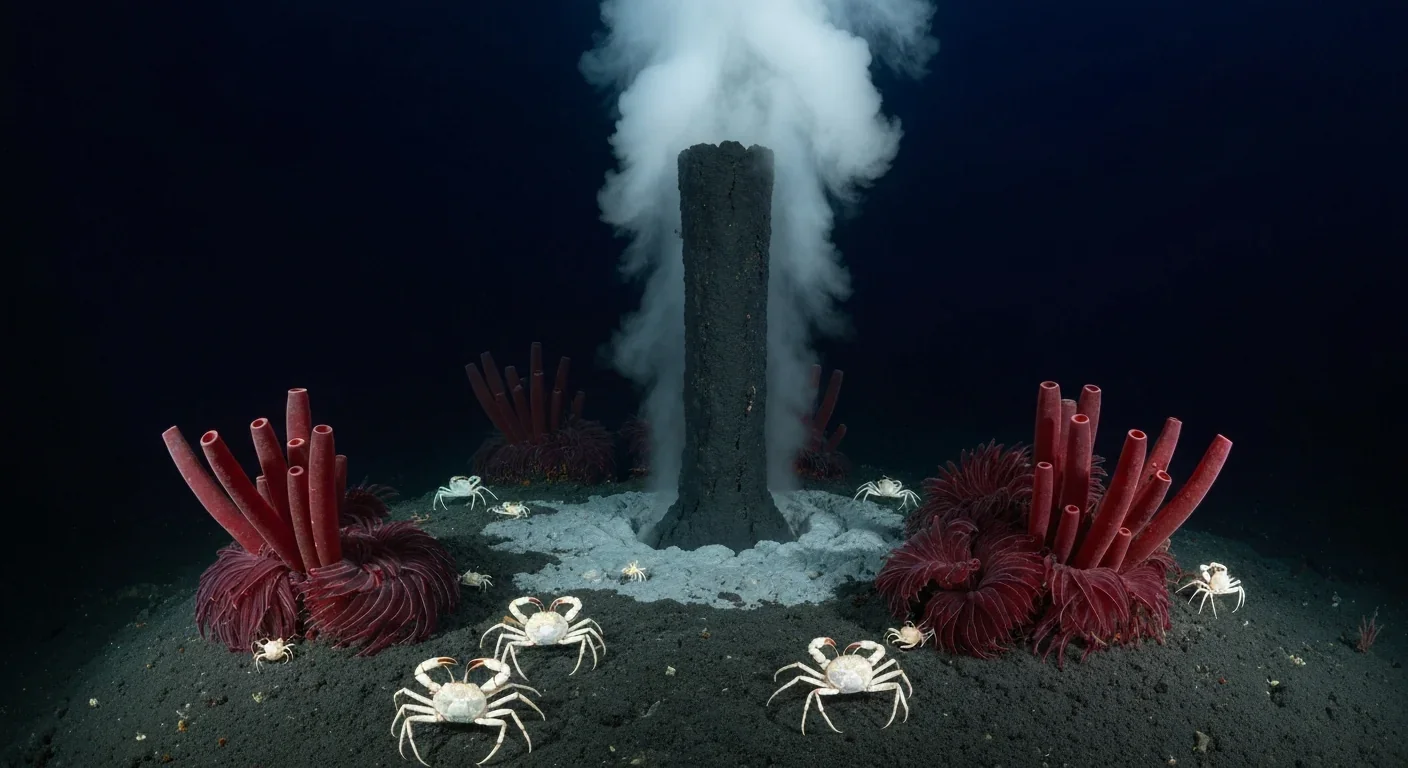

In 1977, scientists discovered thriving ecosystems around underwater volcanic vents powered by chemistry, not sunlight. These alien worlds host bizarre creatures and heat-loving microbes, revolutionizing our understanding of where life can exist on Earth and beyond.

Automated systems in housing - mortgage lending, tenant screening, appraisals, and insurance - systematically discriminate against communities of color by using proxy variables like ZIP codes and credit scores that encode historical racism. While the Fair Housing Act outlawed explicit redlining decades ago, machine learning models trained on biased data reproduce the same patterns at scale. Solutions exist - algorithmic auditing, fairness-aware design, regulatory reform - but require prioritizing equ...

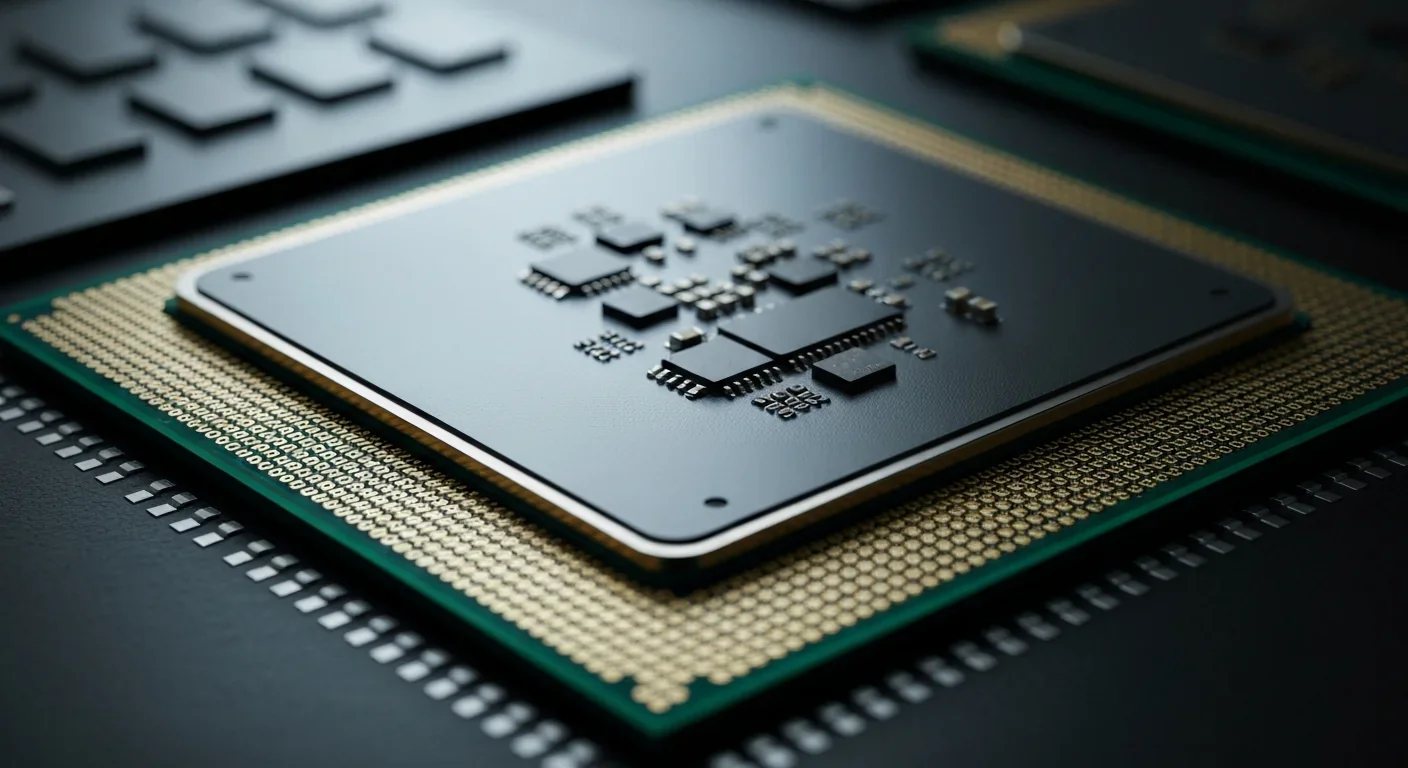

Cache coherence protocols like MESI and MOESI coordinate billions of operations per second to ensure data consistency across multi-core processors. Understanding these invisible hardware mechanisms helps developers write faster parallel code and avoid performance pitfalls.